Using aircrafts as sensors for increased safety on runways

An aircraft is with no doubt an incredible piece of technology. It is full of various sensors itself. In the end, such a big machine needs to – hopefully in the right process order – take-off, fly and land. However, deriving these technologies as an application to increase safety on runways (for taking-off and landing) is something new. The aircraft becomes a runway sensor!

by Dr. Arnaud Varé, Head of Sales, Boschung Mecatronic AG

Safety for taking-off and landing is ensured through the use of various sensors on runways. Very commonly meteorological sensors measure all kinds of atmospheric parameters to provide information on the actual weather. Coupled with meteorological and physical models, weather forecast information can also be provided. Other kinds of sensors are present directly on the runways to detect specific surface conditions to support maintenance as well as air traffic operations. For example, active pavement sensors measure with high accuracy the freezing point temperature of the runway, which is a valuable information to anticipate anti-icing interventions.

Another kind of assessments on the runways is by use of testing vehicles integrating various technologies to determine the friction coefficient of the runway depending on the position. Friction values have been evaluated to provide landing conditions to the pilots. A corresponding table of friction values is usually presented on the Runway Condition Assessment Matrix (RCAM).

Friction coefficient assessments on runways

As said, friction coefficient values have been for a long time measured on runways by specific vehicles. The reliability of such measurements have been under criticism already for some years, not because of the technical solutions, but because of the up-to-dateness of the process. According to the report from the International Airport Review, quick changes of conditions make the results of friction testing assessment irrelevant. Adding that the closure of the runway is necessary to make a measurement by friction testing vehicle, this makes such a method inadequate for future operations.

As suggested at the end of my previous post about runway conditions reporting, the friction coefficient information is still important for runway operations and air traffic management. But how can we get timely information about the friction on the runway and, at the same time, keep the runway open for air traffic? With the only moving part: the only “vehicle” that has always to be on the runway is an aircraft!

Friction coefficient provided by aircrafts

Braking actions of the aircrafts provide valuable data to get an assessment of the actual friction on the runway. The information on the friction gets more precise with the subsequent landings of other aircrafts on the same runway.

Simply stated, the friction is a function of the distance driven by the aircraft and the rotation of the wheel, during the overall braking action. Companies like Safran Runwaiz are experts in the development of algorithms to provide friction coefficient based on aircraft braking actions.

Safran, as a leading supplier of aircraft equipment, especially braking systems for any kinds of aircrafts, has a particular access to such braking action data. Having the appropriate agreements with various airlines, they may securely treat the data in order to support air traffic operations, without the need to make any specific change to the aircrafts.

Safety on runways with timely information

The benefits of such a solution are evident. Air traffic management and runway maintenance operations can share reliable and up-to-date information on runway friction for their respective duties, while not being constrained to possess and maintain heavy equipment such as testing vehicles. The process (and the potential financial loss) of closing the runways for friction assessments is also eliminated.

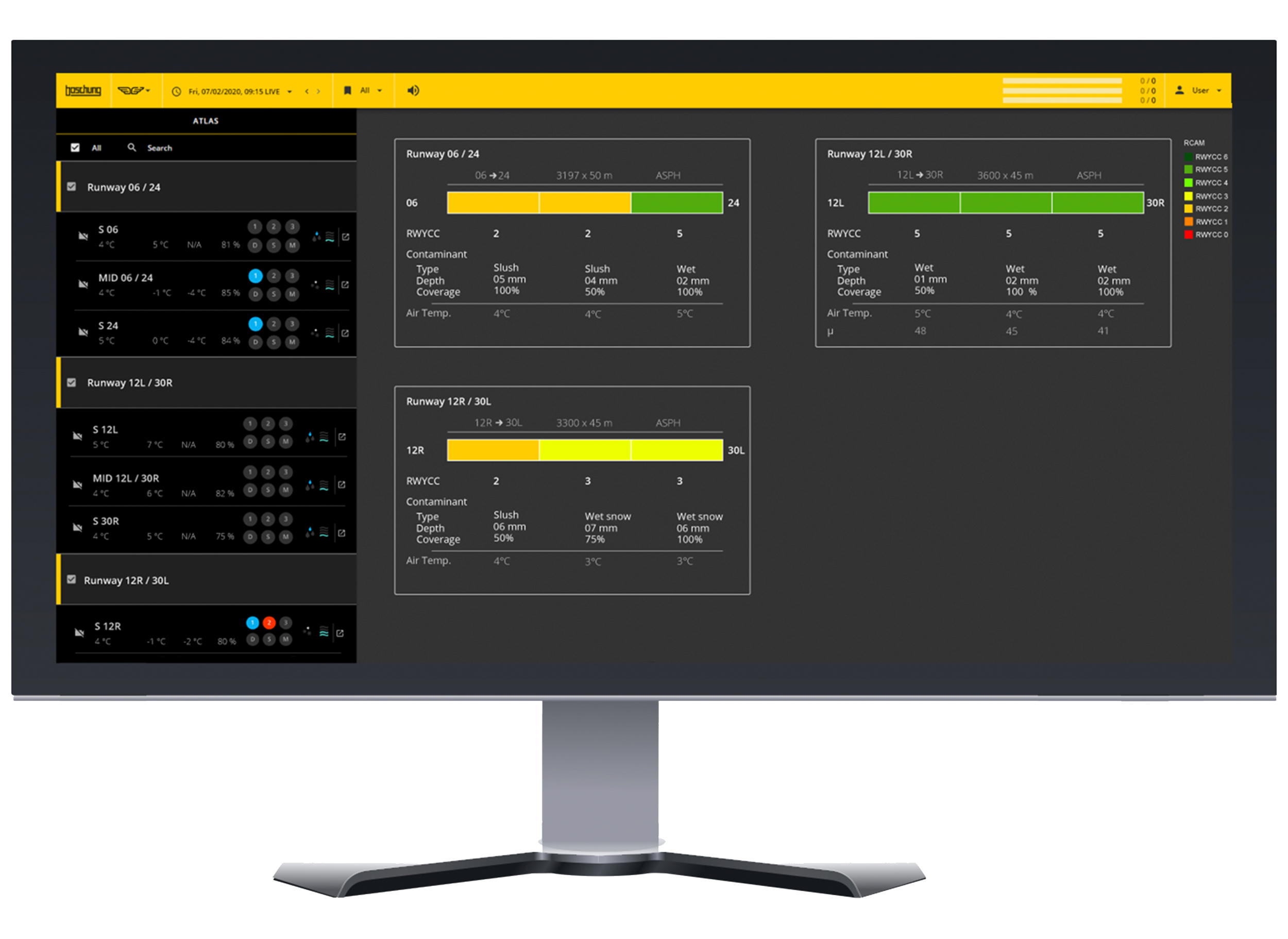

Before the first aircraft lands in the morning, the measurements and detections made by other sensors are very important. Likewise, all along the daily operations, stationary installations such as Boschung’s solution ATLAS have an important role to play and complement aircraft braking data perfectly.

ATLAS / Runwaiz: the combination for highly reliable runway condition assessments

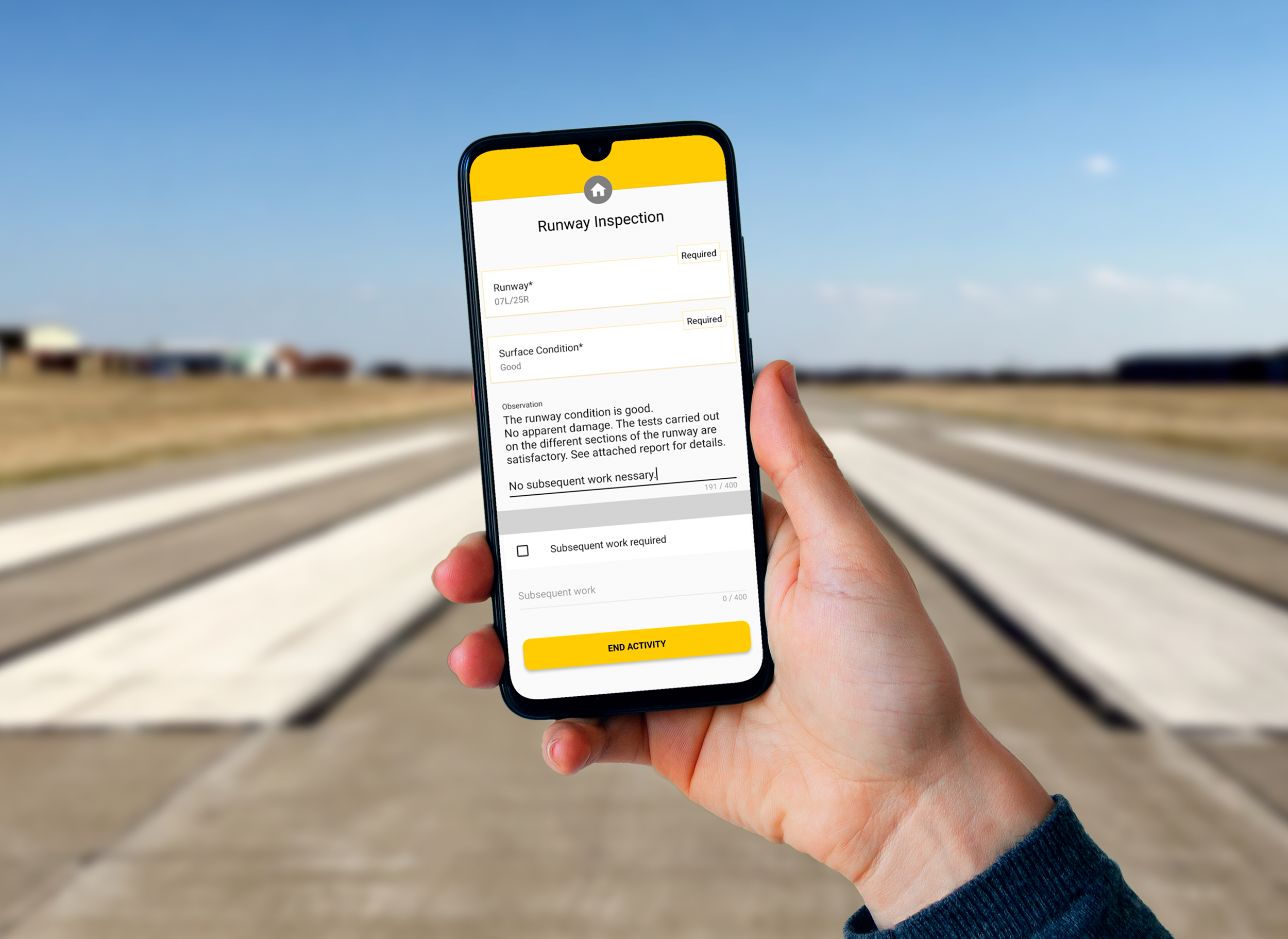

ATLAS – Automated Take-off and Landing Assessment System is Boschung’s solution to automatically provide the elements required by ICAO’s Global Reporting Format (Runway Condition Code, contaminant type, depth and coverage). It bases on stationary sensors linked to a measurement station that deliver live information on runway conditions. The system is available 24/7 so that closures of the runway are not necessary to get the required reporting.

ATLAS is a modular and scalable solution, so that the system is adapted to different characteristics of the airports (airport size, runway length, snowfall frequency). By cooperating with Safran Runwaiz, a new module of the overall solution can be offered to have the information on the friction coefficient of the runway, by means of the aircraft braking data. The combination of the solutions increases the confidence on the runway condition assessments to a very high level, and thus the confidence to eventually provide reliable indications to pilots for taking-off or landing.

ATLAS is a modular and scalable solution, so that the system is adapted to different characteristics of the airports (airport size, runway length, snowfall frequency). By cooperating with Safran Runwaiz, a new module of the overall solution can be offered to have the information on the friction coefficient of the runway, by means of the aircraft braking data. The combination of the solutions increases the confidence on the runway condition assessments to a very high level, and thus the confidence to eventually provide reliable indications to pilots for taking-off or landing.